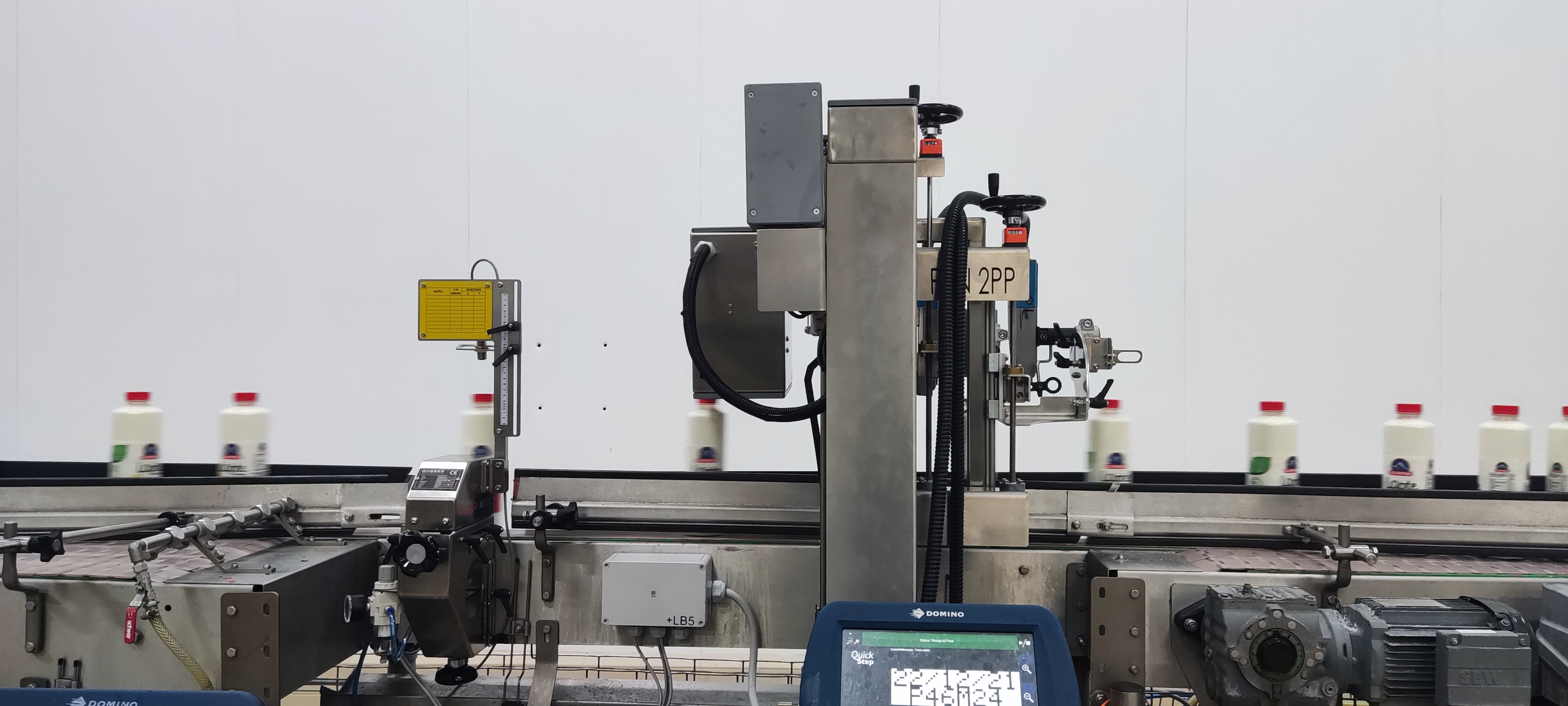

The new modular inspection system ATRAX-360 in production lines of Romania and Greece

ATRAX-360 optical inspection system has been established as the most comprehensive, reliable and simultaneously cost effective solution for 360-degree cap inspection and fill level detection. Its most recent version includes an impressive range of powerful remote units with up to 10 cameras, all in the same central processing unit.

New remote units inspecting:

- Cap logo & color

- Threads defects & dents (ROPP cap)

- Metal injector inside the bottle

- Floating foreign object

- Label

- Barcode

- Printing (On the cap or on the bottle)

- Full case inspection (with QUBBER FCI)

- Fill level with X-RAY technology

Great efficiency and ease of use:

- New printing reading algorithms (OCR technology)

- New algorithm to eliminate Fault Rejections, caused by hard to read printings

- Improved User Interface and easier configuration menu

- Impressive cost/benefit ratio