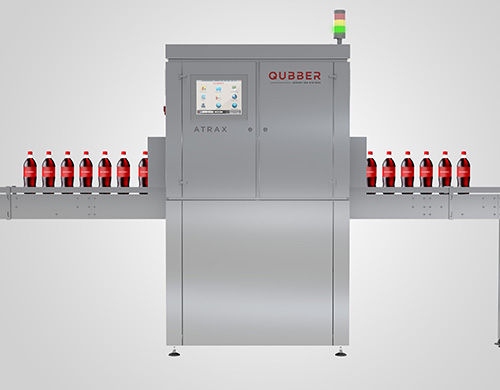

ATRAX 360

Full bottle

With ATRAX 360 series QUBBER detects even the tiniest closure defect of plastic and glass containers, thus ensuring the end customer safety and brand protection.

ATRAX 360 is an extremely accurate optical inspection system that, due to its modular architecture, combines a meticulous 360-degree inspection of the closure with detailed inspection of the container’s fill level, closure color and logo inspection, label inspection, barcode reading, printing inspection (date/lot nr,), metal injector detection, floating foreign object detection and full case inspection.

It is a unique system suitable even for high speed filling lines (up to 80,000 items/hour) of water, beverage and food (milk, juice etc.) industries.

- Minimizing customer complaints

- Ensuring brand name

- Improved safety and comfort to use for the end customers

- Early diagnosis of Filler/Capper and Labeling machine malfunctions

- Improvement of overall equipment efficiency through statistical analysis of the production

- Avoidance of costly production downtime

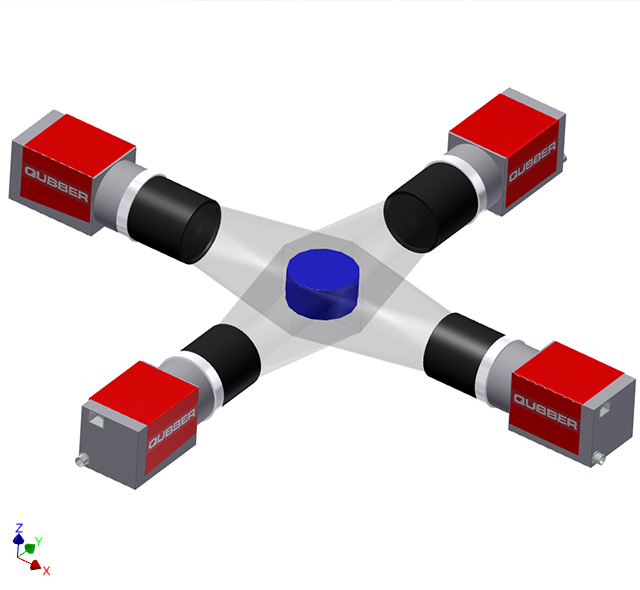

- 360-degree closure inspection with 4 cameras

- Simple integration into existing production lines

- Automatic height adjustment

- No cooling unit required

- Inspection of transparent plastic and glass containers of different colors and closures

- Capper heads and Filler valves management, along with statistical analysis

- Drop Bridge (Detects and rejects fallen containers)

- Operating performance up to 80,000 items/hour

- Closure presence

- Cocked/ tilted/ high closure

- Tamper band defects (broken/ missing/ folded under/ hanging)

- Logo inspection

- Color inspection

- Threads defects detection (ROPP cap)

- Dents (ROPP cap)

- Overfill / Underfill

- Foaming compensation

- Presence

- Positioning

- Flag effect

- Rotation

- Correspondence to selected recipe

- Presence

- Reading (OCR/OCV technology)

- Reading with image-based technology

- Detection of metal injector at the bottle's bottom

- Detection of non transparent floating foreign object

- Correct number of products presence in cartons, crates and shrink film packaging

- Wrong placement of products

- Carrying handle inspection (e.g Water bottles packaging)

- Stainless steel construction that conforms to sanitary regulations

- High-resolution industrial cameras

- High performance industrial computer

- Long-life industrial LED lighting

- 17’’ industrial touch screen

- UPS unit

- Separate automation unit

- Light tree and siren

- Motorized height adjustment

- Rejection devices

- Rotating HMI console

- Air Bridge (removes water drops)

- Statistical analysis software (QUBBER Q-Report)