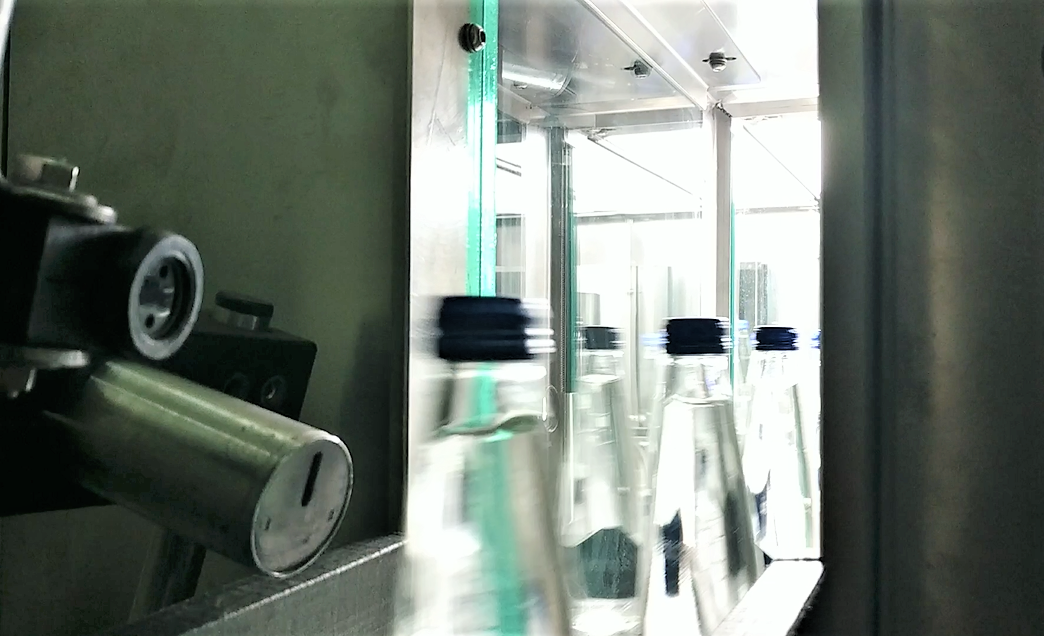

ATRAX 360-R

A state of the art inspection system specialized in Ropp closure inspection of clear glass bottles. Specially designed to detect all kinds of defects in metal Ropp caps, along with fill level, label, printing and foreign object detection.

- Improved safety and comfort to use for the end customers

- Improved safety for the supply chain (storage, transportation and distribution)

- Ensure brand name

- Early diagnosis of Filler/Capper malfunctions

- Avoidance of costly production downtimes

- Reduced false rejections through advanced algorithms for fill level inspection

- 360-degree closure inspection (Ropp type)

- Simple integration into existing production lines

- Automatic height adjustment with electric motors

- No cooling required

- Detailed detection of defects in the ironing of the cap

- Detailed inspection of the side and top tearing of the cap

- Capper heads and Filler valves management, along with statistical analysis

Closure

- Closure presence

- Cocked/tilted/high closure

- Tamper band defects

- Side ironing

- Torn caps from above

- Torn caps on the side

- Upper Logo inspection

- Underfill / Overfill

- Label presence

- Label placement and alignment

- Correct label according to the recipe

- Printing presence

- Printing quality (OCR/OCV technology)

- Detection of opaque floating foreign objects

- The size and the position of the object may affect the inspection accuracy

- Rejection device

- Rotating HMI console

- Air bridge (removes water drops)

- Report software package (Q-Report)