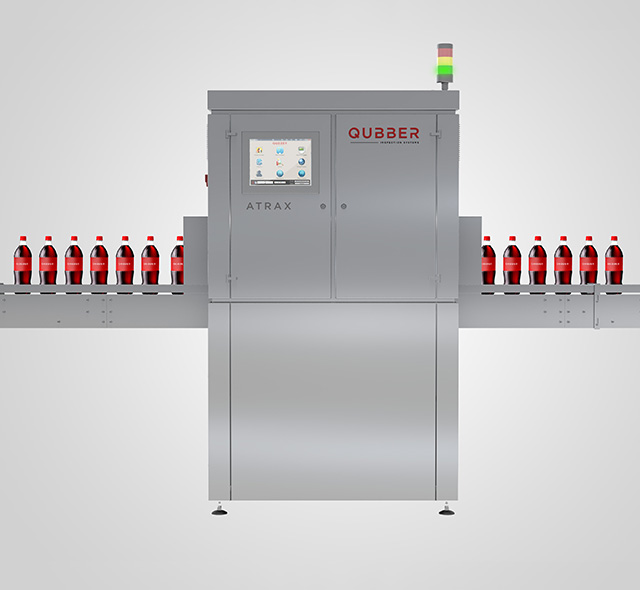

ATRAX Q3-CLF1

Full bottle

Atrax Q3-CLF1 is one of our most sophisticated vision systems, combining all inspections (closure, fill level and label) in one compact unit. It is suitable for the inspection of PET and glass containers of water, beer and beverages and it has been designed for high production speeds.

- Improved safety for the end customers

- Ensuring brand name

- Early diagnosis of Filler/Capper malfunctions

- Avoidance of costly production downtimes

- Save raw material through exact fill level adjustment

- Reduced false rejections through advanced algorithms for fill level inspection

- Inspection of transparent plastic and glass containers of different colors and caps

- Inspection of plastic and metallic closures (crown, ropp)

- Transparent, opaque and foamy liquids

- Simple integration into existing production lines

- No spacing between containers required

- No cooling required

- Capper heads and Filler valves management, along with statistical analysis

- Drop Bridge (Inspects and rejects fallen containers)

- Operating performance up to 80,000 containers/hour

Closure (two areas of view)

- Closure presence

- Cocked/ tilted/ high closure

- Tamper band defects (broken/ missing/ folded under/ hanging)

- Overfill / Underfill

- Foaming Compensation

- Presence

- Alignment

- Stainless steel construction that conforms to sanitary regulations

- High-resolution industrial cameras

- Long-life industrial LED lighting

- High performance industrial computer

- 17’’ industrial touch screen

- Separate automation unit

- Light tree and siren

- Motorized height adjustment

- Rejection device

- Rotating HMI console

- Air Bridge (removes water drops)

- Remote printing inspection unit

- Software package (Q-Report)