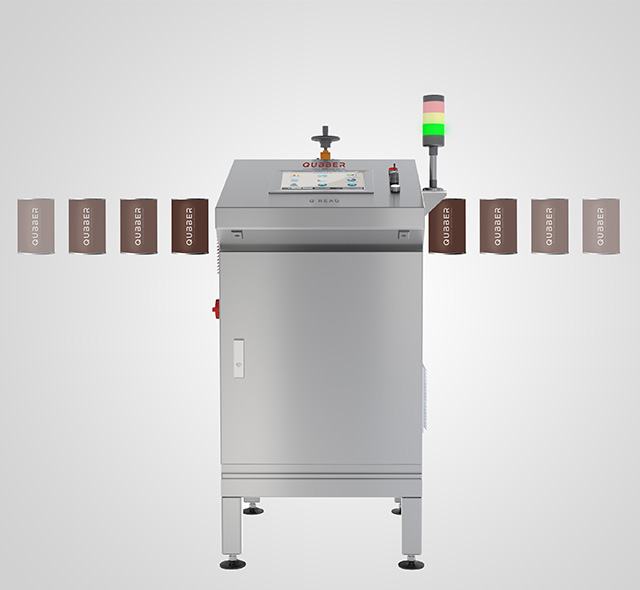

Q-READ

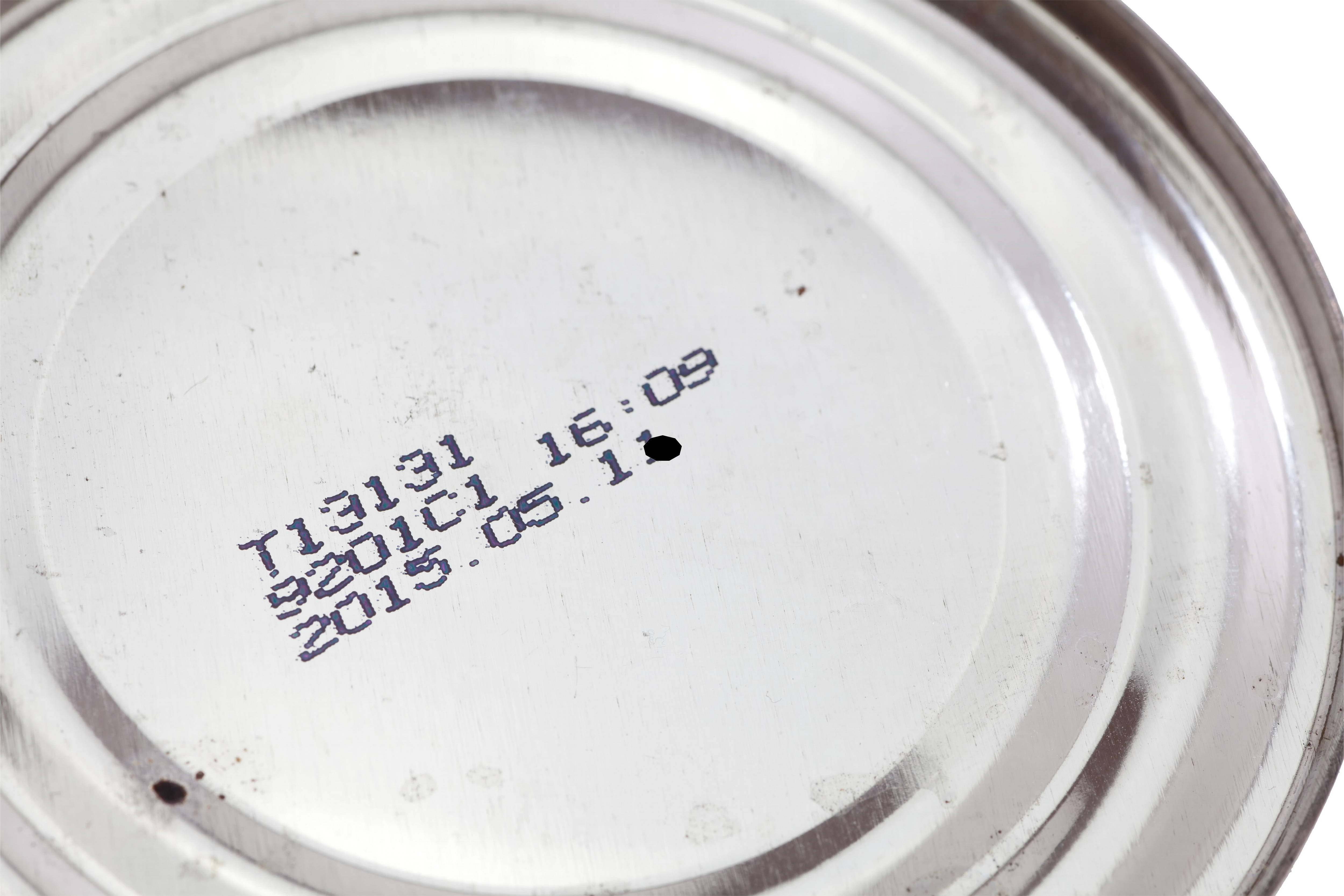

Date / code

Incorrect printings on can containers increase company costs, mainly because of re-evaluation and recalls. Q-Read inspection system is specialized in reading and verifying printed characters (e.g best-before date and production number) using OCR/OCV technology. The whole system is integrated in metal can production lines of food industry, eliminating the risk of non-compliant products reaching consumers.

- Timely detection of any print quality problem

- Saving of costs due to minimization of lot rechecks and recalls

- Increased line efficiency

- Brand name protection

- Ease of use

- Multiple language OCR technology (English, Arabian etc)

- High characters read rates

- Handles process variations (e.g surface background compensation)

- Operating performance up to 45,000 items/hour

- Missing printed character or line

- Wrong characters

- Cut-off printing

- Poorly-printed or confusing characters

- Cut-off/shrunk/smudged printing

- Floor-base support system

- Integration above or under the conveyor belt

- High-resolution industrial camera

- Long-life strobe LED lighting

- High performance industrial computer

- 17’’ industrial touch screen

- Additional inspections by installing more camera modules

- Rejection device

- Software package (Q-Report)