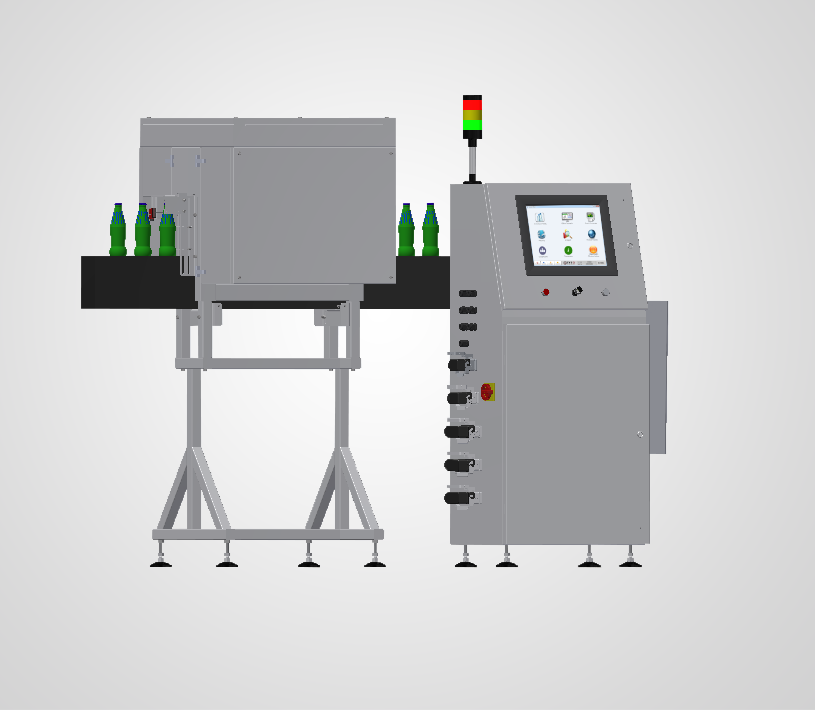

Q-LABEL 360

Label

An advanced modular system equipped with 6 cameras providing both label inspection and date/ lot verification of non-oriented bottles at line speeds up to 55,000 bottles/ hour.

- Timely detection of malfunctions in labeling machine

- Saving of costs due to elimination of rechecks and recalls

- Flawless product appearance

- Brand name protection

- Inspecting glass or plastic bottles, up to 0.5 lt, regardless of the bottle or liquid color

- Easy-clean design

- Integration without interrupting the production line

- 360-degree bottle reconstruction based on QUBBER’s P-Train algorithm

- Quick changeover

- Encoder-based rejections

- Operating performance up to 55,000 bottles/hour

- Label inspection module- after the labeling machine

- Label presence

- Label positioning and alignment

- Flag effect

- Printing presence

- Missing printed character or line

- Wrong characters

- Poorly printed or confusing characters

- Cut-off/ shrunk/ smudged printing

- Stainless steel constructions

- Compact central unit

- Label inspection module with six high resolution cameras

- High performance industrial computer

- 17’’ industrial touch screen, front panel NEMA4/ IP65

- Long life strobe LED lighting

- Data exchange

- Statistical software QUBBER Q-Report

- Multi-language interface