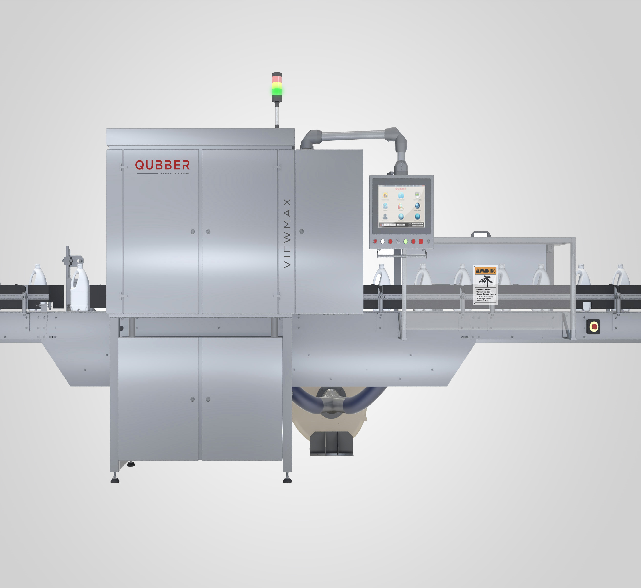

VIEWMAX

Empty bottle

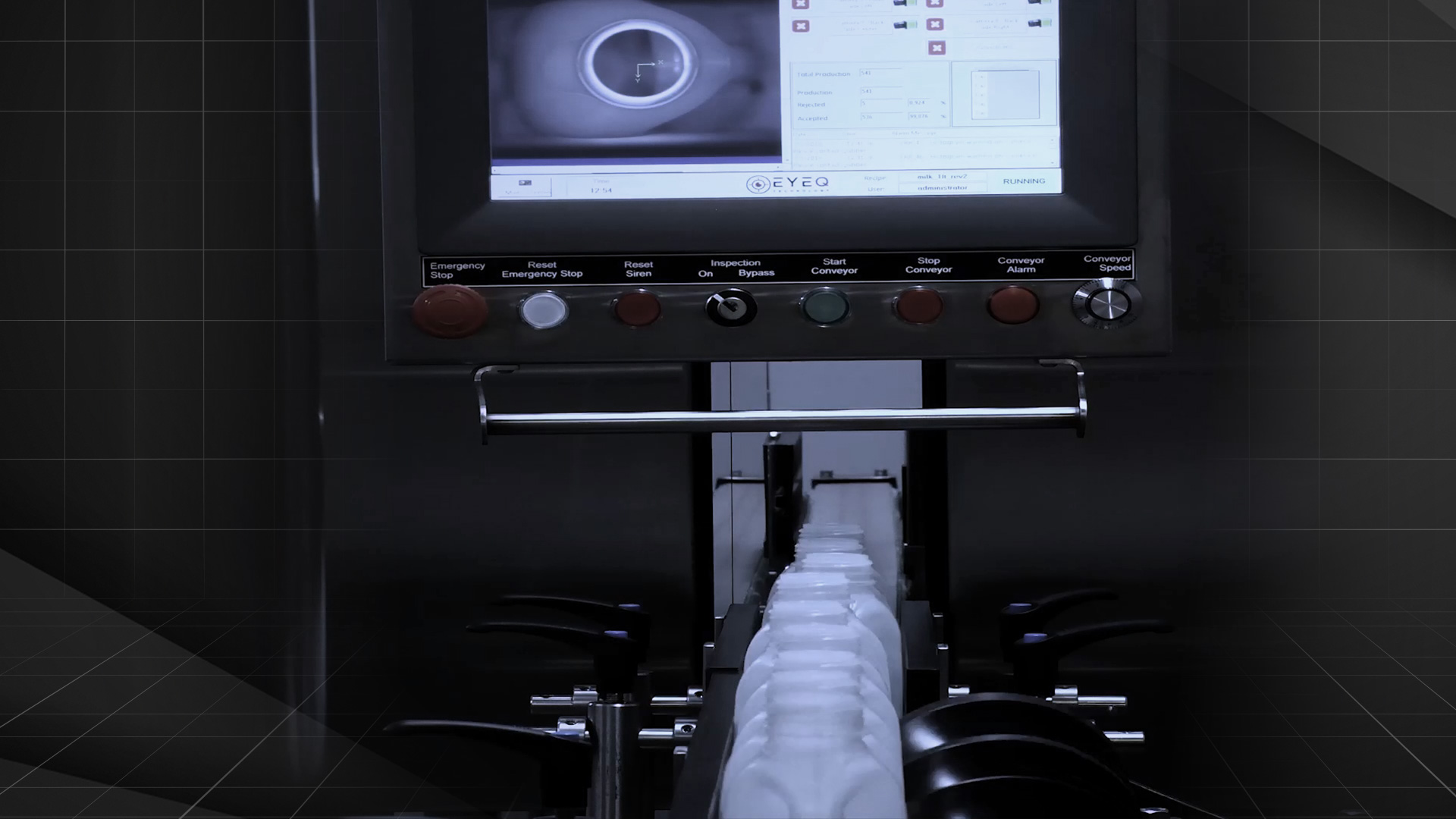

QUBBER VIEWMAX is an extremely efficient inspection system that detects imperfections and pinholes on sidewalls, neck and thread of empty HDPE bottles. Based on QUBBER EYEQ multi-camera technology and due to its advance design, VIEWMAX thoroughly inspects and successfully detects all the defective bottles, thus ensuring the filling process and protecting the quality of the filled liquid. As HDPE bottles are a popular packaging choice for the dairy and fresh juice industries, QUBBER VIEWMAX inspection system finally contributes in the end customer safety and comfort to use.

- The all-surface inspection of VIEWMAX ensures that only good bottles are allowed to enter the Filler

- Lightweight bottles inspection is possible, due to the advanced design of QUBBER VIEWMAX

- Early diagnosis of injection molding machine malfunctions

- Improved safety and comfort to use for the end customers

- Ensuring brand name

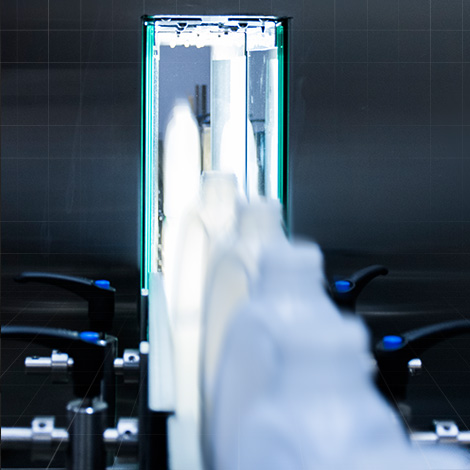

- All-surface inspection of lightweight HDPE bottles of different sizes

- Detection of non-transparent spots and pinholes with very small dimensions

- High accuracy and repeatability

- Completely automated for easy integration into existing production lines

- Operating performance up to 24,000 items/hour

Bottle body

- Non transparent impurities

- Deformations

- Burn marks

- Pinholes

- Ovality

- Internal diameter

- Flashing

- Contamination

- Dimensions fluctuation

- Damaged thread

- Stainless steel construction

- Integrated vacuum conveyor belt synchronized with the line speed

- Integrated screw conveyor with different screw sizes according to bottles sizes

- High-resolution industrial cameras

- Long-life industrial LED lighting

- High performance industrial computer

- 17’’ industrial touch screen

- Separate automation unit

- Light tree and siren

- Motorized height adjustment

- Rejection device

- Rotating HMI console

- Data exchange

- Software package Q-Report

- Multi-language interface