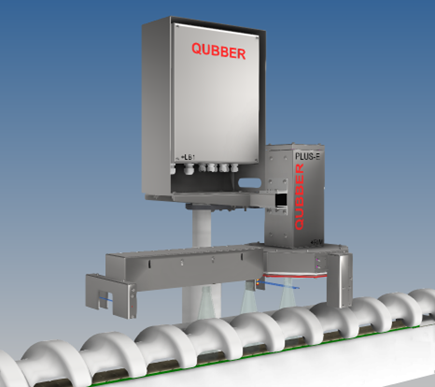

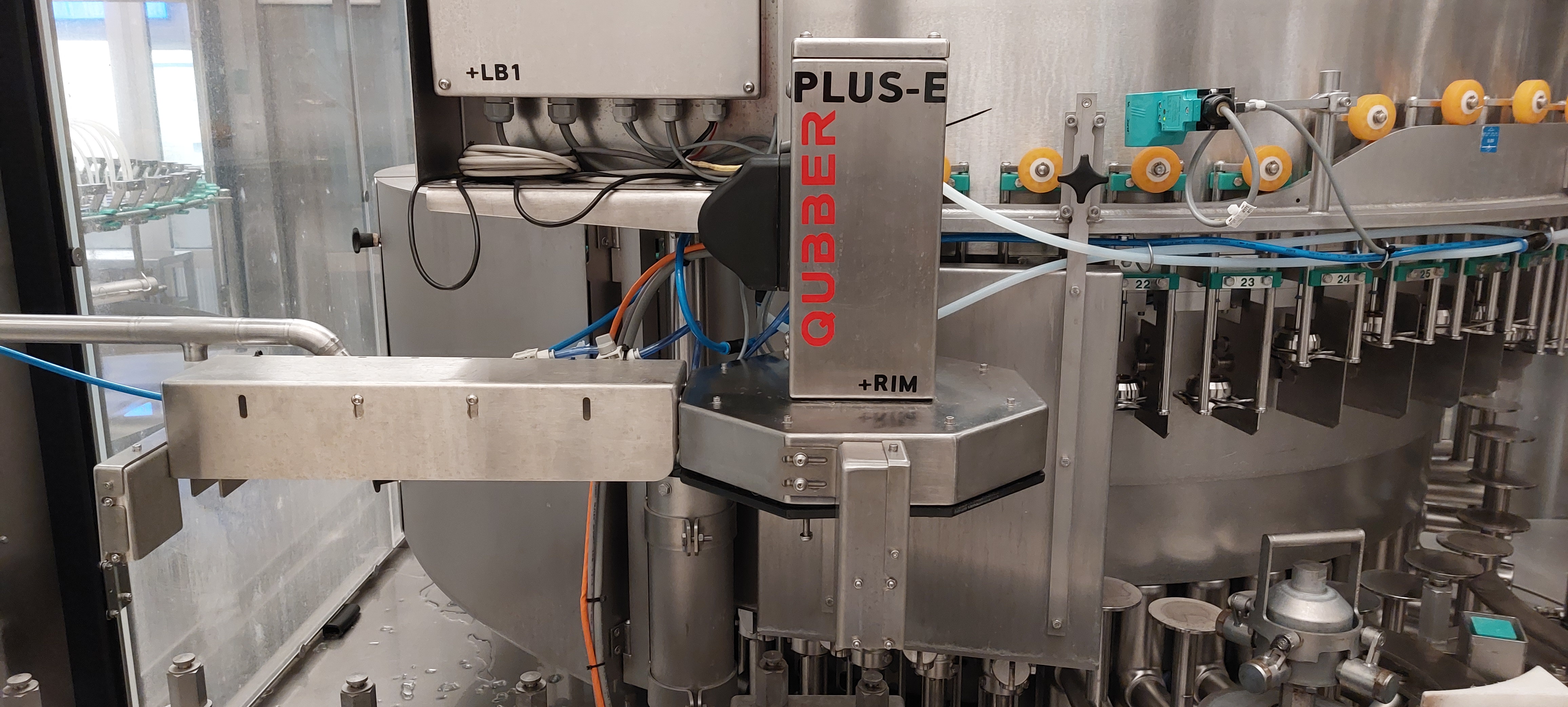

QUBBER PLUS-E

Empty bottle

The problem that has been occurring in the recent years on the rim of glass bottle demanded until now the installation of an integrated system EBI Empty Bottle Inspector.

QUBBER PLUS-E is a highly efficient and reliable system dedicated exclusively to the detection of defects on the rim of empty glass bottles.

It is installed at the entrance of the Filler. Any problematic bottles get discarded at the exit of the Filler.

QUBBER PLUS-E is used in water bottling production lines and soft drinks.

- Ensuring the quality of the product

- Space and cost savings as EBI is not required

- Avoid consumer complaints

- Affordable high-tech solution

- Easy installation at existing or new lines

- Checking for defects on the rim

- Aluminum construction

- Compact construction

- Electric board

Closure

- Closure presence

- Cocked/ tilted/ high closure

- Tamper band defects (broken/ missing/ folded under/ hanging)

- Logo inspection

- Color inspection

- Threads defects detection (ROPP cap)

- Dents (ROPP cap)

- Overfill / Underfill

- Foaming compensation

- Presence

- Positioning

- Flag effect

- Rotation

- Correspondence to selected recipe

- Presence

- Reading (OCR/OCV technology)

- Detection of metal injector at the bottle's bottom

- Detection of non transparent floating foreign object