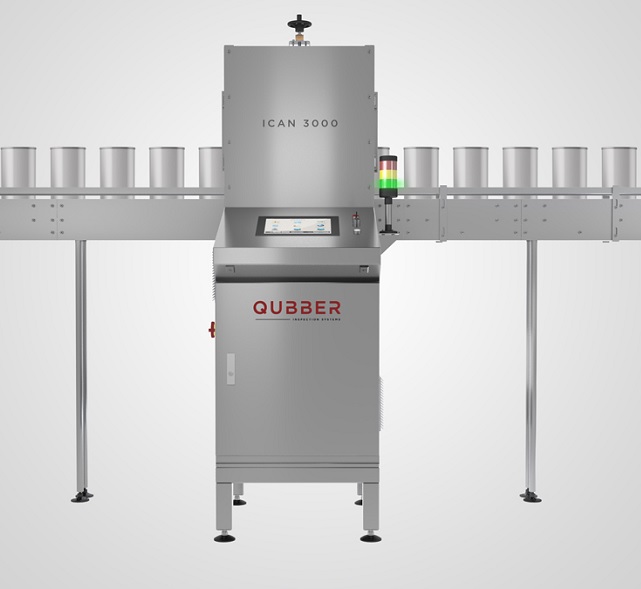

i-CAN 2000/3000

Empty can

A single deformed can may jam the whole production line. QUBBER i-CAN 2000/3000 inspection system prevents this from happening, by detecting in great detail and accuracy, foreign objects and defects on the seal, bottom and inner sidewalls of can containers. Our inspection is applied in two or three-piece steel or aluminum cans.

QUBBER i-CAN 2000/3000 inspection system is usually integrated in the conveyor line prior to the Filler/Closer system, ensuring ideal conditions for the filling and sealing process.

QUBBER i-CAN 2000/3000 is suitable for beer, beverage bottling and food industry.

0

22 kinds of defects

0

0,5mm minimum foreign object dimensions

0

16 items/ second

- Avoidance of filling the problematic cans

- Avoidance of malfunctions in Filler/Closer

- Increased line efficiency

- Cost saving

- High product safety

- Compact system with one inspection module (i-CAN 2000)

- Expandable system with up to three inspection modules (i-CAN 3000)

- Operating performance up to 60,000 items/hour

- Full-adjustable by operator

- Simple integration into existing or new production lines

- Low operating cost

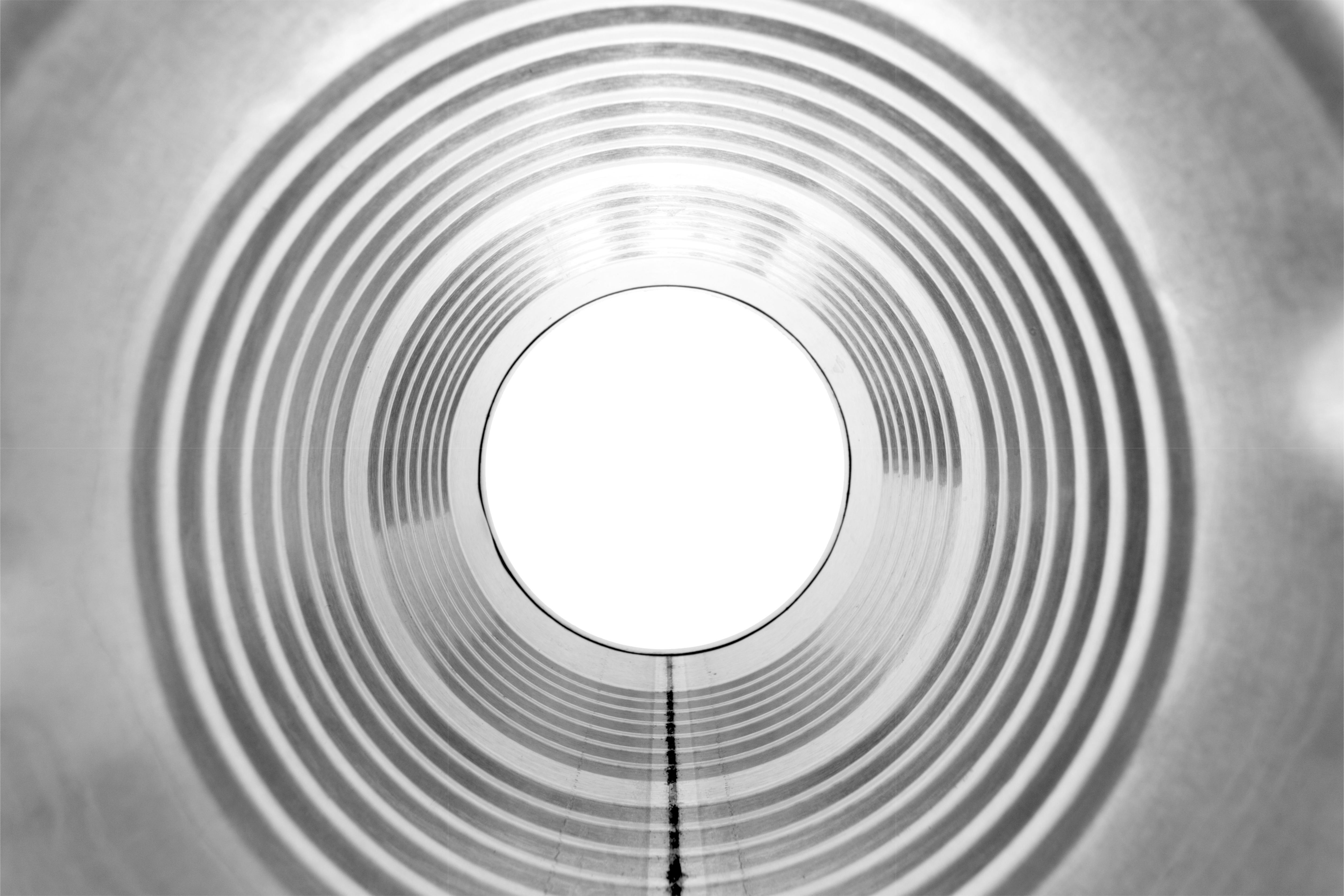

Omni-view module

1st inspection, Seal:

1st inspection, Seal:

- Ovalization

- Dents or defects

- Can upside/down

- Foreign objects

- Dents

- Lack of protecting film on the welding

- Wrong folded can (The coated surface is outwards)

- Foreign objects

- Dents

- Ovalization

- Seal dents down to 0,5mm

- Can upside/down

- Opaque or semi-transparent foreign objects down to 1x1mm size

- Dents inspection with high sensitivity

- Height-adjustable stainless steel & aluminum construction

- High-resolution industrial cameras

- Long-life strobe LED lighting

- High performance industrial computer

- 17’’ industrial touch screen

- Rejection device

- Software package (Q-Report)

- Vacuum or magnetic conveyor, if requested